When designing a product with Aluminium as a material component, you will surely evaluate what is optimal in terms of production techniques for this specific metal. Even though there are other processes for shaping aluminium, die casting is typically one of the best possibilities.

Precision die casting is a typical production method used by many sectors that work with metals. It includes injecting molten metal into a die cavity under high pressure. While die casting may be done with various metals, aluminium is still one of the most often used materials, making the combination of the die casting technique and the usage of aluminium ideal.

Explanation of the Die Casting Process

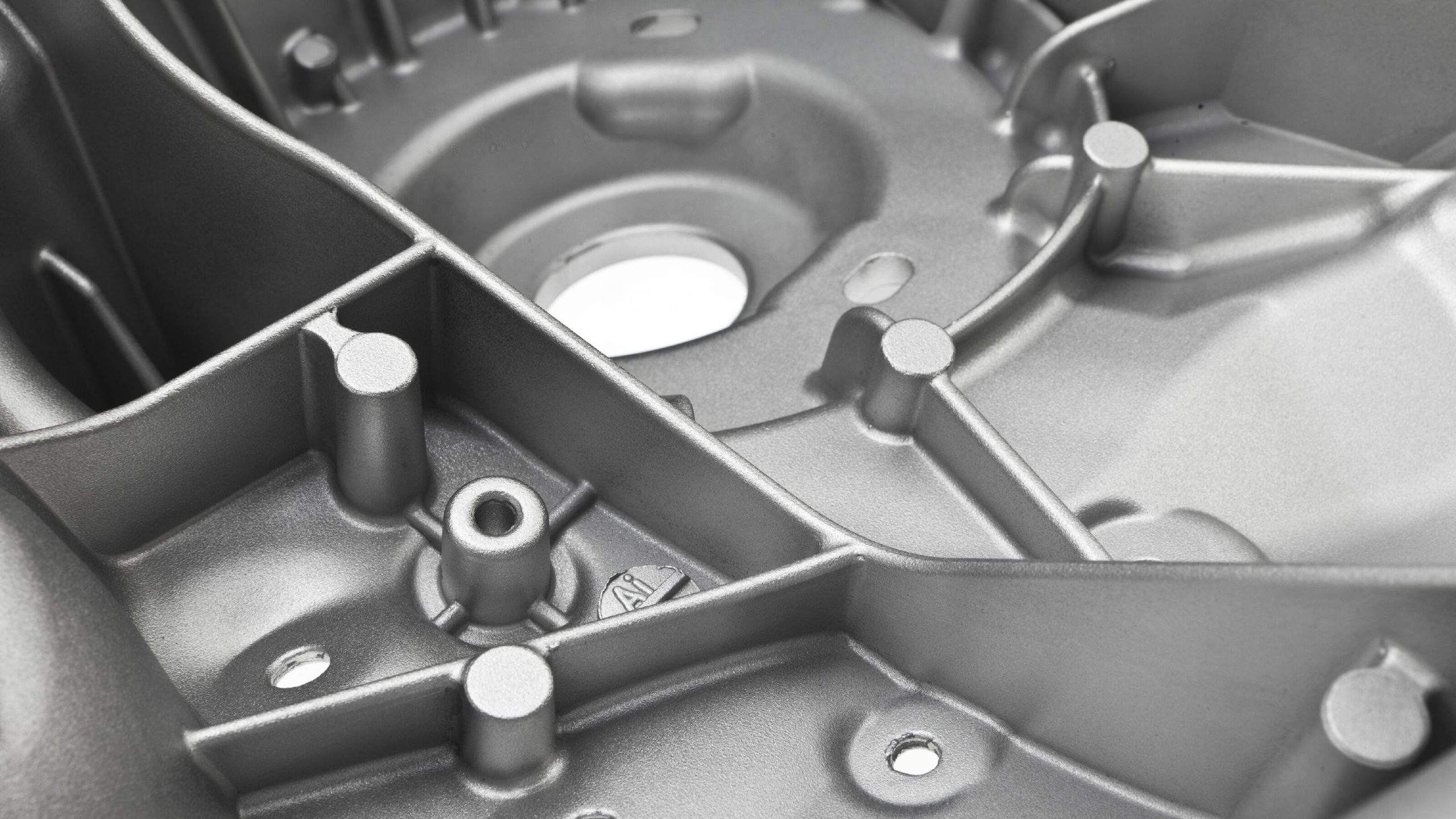

As previously said, aluminium die casting is a method that aids in the creation of complicated parts that are extensively employed in a variety of sectors. Automotive, industrial, and telecommunications products are only a few examples. First and foremost, in the die casting process, aluminium ingots are heated to the point of becoming molten. The liquid aluminium is then pumped under pressure into a die cavity. After solidification, the die, which is made up of two pieces, is unclamped and separated to expose the cast aluminium component in the desired shape and size.

Because of the quality of the production process, the finished product has a smooth surface and requires minimum machining. Furthermore, because the die is constructed of steel, the die casting process is repeated several times with the same mold until it deteriorates. As a result, aluminium die casting is a high-volume production method.

Aluminium’s Benefits Casting Die

aluminium as a material has the following benefits:

- It is adaptable: There are several finishing options available, allowing the look of a product to be customized.

- It has outstanding material properties: Aluminium is a soft and pliable metal. It is also a metal that can withstand high working temperatures and is resistant to corrosion.

- It has lightweight: Because of its composition, aluminium may be utilized to make lighter parts and components without sacrificing durability.

- It is easy to work on: Aluminium is a material that is easy to cast, allowing for the creation of a wide variety of items.

Other Considerations

Here are some extra things to think about while designing and manufacturing aluminium die casting products. These are their names:

Allowance for Machining

The amount of stock that material producers can remove from a finished die cast product is referred to as the machining allowance. If the sum is insufficient, the project may be unable to proceed. Optimal mechanical characteristics and density at the casting’s surface are critical considerations throughout the aluminium die casting process.

The thickness of the Wall

Most aluminium die casting projects require homogeneous wall thickness. Adjust the procedure gradually if the end result demands a changing degree of thickness. Thinner walls can assist save money on materials and make the workpiece lighter. Aside from reaching the proper thickness, uniformity across the component is critical.

The Assembly Procedure

Assembling complicated workpieces necessitates the use of procedures such as welding, threading, and fastening. Complicated assembly will need a number of phases before the technique is completed. since a result, identifying the proper procedures during the planning phase is critical since it will impact the overall design of the product.

Material contraction

In aluminium die casting, shrinkage must be taken into account. Metal will shrink throughout the cooling and solidification processes. aluminium die casting product designs with narrower parts can be produced to reduce this impact. It is worth noting that thicker sections of the workpiece are more prone to shrink and cause surface porosity.

Do you require high-quality aluminium die casting services for your production requirements? Global-Pacific Manufacturing is the answer as they are a top famous aluminium die casting manufacturer in Malaysia! Choose Global-Pacific Manufacturing for all of your aluminium die casting needs instead of settling for inferior manufacturing services. Get in touch with them today to learn more and get started!