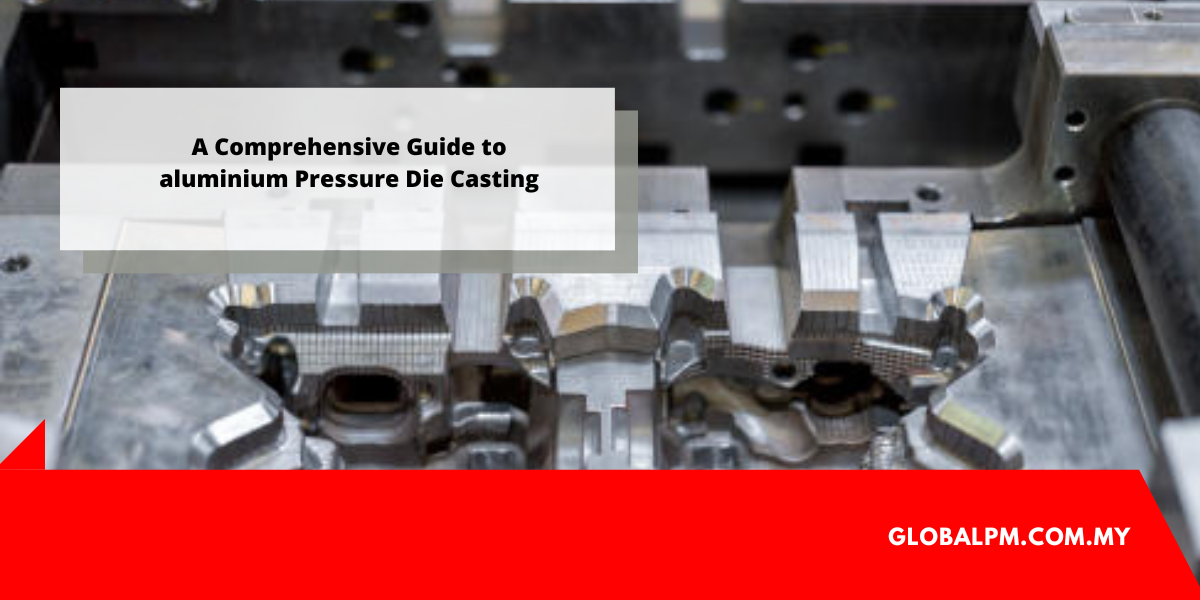

What precisely is aluminium Pressure Die Casting?

Die casting is a procedure that allows for the production of low-cost aluminium or other metal castings at rapid speeds and under high pressure.

The aluminium pressure die-casting technique is used for producing aluminium components because it is dependable and suited for producing similar parts in large quantities.

The molten aluminium is injected into the dies with pressure using an injection technique in this process, which is automated and highly fast. As a result, when used for mass manufacturing, the process is quick and precise.

aluminium die casting is utilized in electronics, aircraft, hardware, and automobiles.

- Because the aluminium pressure die-casting technique produces similar components with improved quality, companies that require a large number of the same components may profit from it.

- Because of mass manufacturing, this procedure can produce high-quality items with exceptional precision, and the best part is that they are inexpensive.

- The procedure is quick. It does not take long for the molten form of aluminium to cool.

- It is capable of producing aluminium components for a variety of applications and works well with accurate pieces with complicated geometry.

- The surface quality of aluminium components produced by the aluminium pressure die-casting technique is likewise quite good.

- This method is also appropriate for producing aluminium castings with thin walls, resulting in lightweight components.

aluminium Factors to Consider Casting Die

aluminium die casting is one of the most conventional ways for producing aluminium cast items; it necessitates certain important considerations, which are addressed below:

Die Construction

The pressure die casting method for aluminium includes various crucial components, one of which is the die. Because the die will forecast the design and arrangement of the real component, it must be flawless.

It is critical to keep the die efficient and simple to use so that when the time comes to remove it and obtain the aluminium portion, you can do it with ease. While designing the mold, keep the parting line in mind.

Post-Finishing Processes for aluminium Components

Once the manufacturing of the aluminium parts is carried out using the pressure die casting process, the surface is most of the time finished and smooth. However, sometimes such components need an additional finishing on the surface, which could comprise the following options.

Anodizing

The die-cast aluminium can be anodised to increase corrosion resistance and longevity. Anodizing is the process of applying a protective coating to aluminium objects.

Although aluminium has a high conductivity, the anodized coating applied is non-conductive and so aids in the electrical insulation of the metal component.

Because of the lack of conductivity provided to such components, they may not be acceptable for electronic applications; thus, different coating processes should be utilized for electronic applications.

Powder Coating

Powder coating is another typical process used after aluminium die casting. This procedure takes place at a greater temperature and is difficult to execute. However, by applying a powder coat, the components become scratch resistant while also adding various textures and a glossy appearance.

Chemical Film

The aluminium die casting can also be supported with a finishing procedure known as chem film, in which the components are sprayed or brushed to apply the chem film. It improves the components’ electrical conductivity.

Do you require high-quality aluminium die casting solutions Malaysia for your production requirements? Global-Pacific Manufacturing is the answer! Choose Global-Pacific Manufacturing for all of your aluminium die casting needs instead of settling for inferior manufacturing services. Get in touch with them today to learn more and get started!